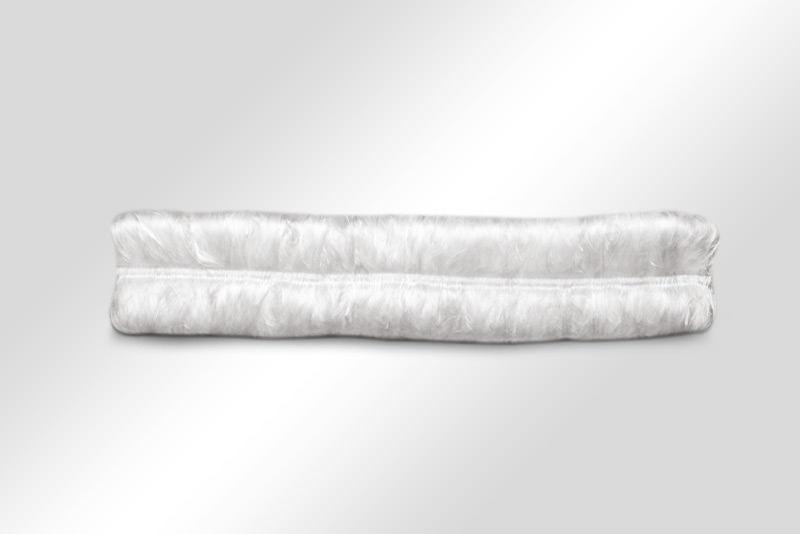

Nothing but pure fibers.

iTEX epack is a long-lasting absorption solution that helps optimize acoustics in the exhaust system even in the toughest conditions. This insulating material is also highly environmentally friendly as the textile glass fibers are completely free from organic binding agents and materials. iTEX epack is low-emission and recyclable, helping you comply with the increasingly tough exhaust emission standards.

Because of the lack of limitations such as binding agents or plastic bags/nets, acoustic effectiveness is evident straight away. iTEX epack can also be produced and supplied with any continuous fiber (E glass, ECR glass, or S glass).

Technical properties

(version depends on application temperature)

| iTEX epack750 (up to 750 °C) |

iTEX epack600 (up to 600 °C) |

|

| Raw material: | ECR glass fiber | E glass fiber |

| Filament diameter (nominal): | 18 – 27 μm | 18 – 27 μm |

| Linear shrinkage: | ≤ 1% | ≤ 1% |

| Loss on Ignition: | ≤ 2% | ≤ 2% |

| Chemical composition (ave. in weight %): |

1. SiO2: 60 +/- 2

2. CaO: 21,5 +/- 1,5 3. MgO: 3 +/- 1 4. Al2O3: 12 +/- 2 5. TiO2: 1,25 +/- 0,75 6. K2O+Na2O: < 1 7. Other: ≤ 2,5 |

1. SiO2: 54 +/- 2

2. Al2O3: 14 +/- 2 3. B2O3: 7,5 +/- 2,5 4. MgO-CaO: 23 +/- 7 5. K2O+Na2O: < 2 6. Other: ≤ 2,5 |